Many of you will know that UPS’s are not a one size fits all solution.

So, what happens when a jumbo-sized UPS is needed to power airport infrastructure? (pun intended)

Who are you going to call?

No… you don’t call the Ghost Busters. You call us!

Background

The underpass was built to allow local traffic to pass under the new Airport runway.

The underpass itself is below sea level and thus requires flood mitigation protocols, along with emergency power systems in case of a mains power failure.

A three phase UPS is needed to backup:

- Water pumps

- PLCs

- Emergency hazard lights

- Security systems

This is all controlled from a raised transportable air-conditioned switch room. The switch room, which also houses the UPS and battery cabinets, is located on a 2-metre-high raised platform adjacent to the underpass. The room provides a controlled environment for electrical equipment, enhancing safety, reliability, and service life.

Situation

Batteries for the three phase 40kVA UPS have reached end of life and are due for replacement.

Two large battery cabinets house two strings, totalling 72 x 12V 110Ah, 10 year design life batteries to provide the required battery backup in case of a mains power outage. The batteries are front terminal allowing for a smaller footprint within the battery cabinet. Each battery weighs 35kg. Total weight = 2.5 tonnes.

Dryandra Underpass Battery Cabinets

The Problem

The task – to replace UPS batteries. Simple right? Not so much! Swapping out the batteries would be an everyday bread task, but getting batteries into (and out of) a room in this location for the swap out will be far more challenging and require some serious planning.

The Switchroom

Remember! The transportable switch room is located on a 2-metre-high raised platform. Entry is via a set of metal rung steps and a grated galvanised safety platform. From the platform there is a step up to the entrance of the room that also must be negotiated.

It is immediately apparent that moving 2.5 tonnes of batteries into position in the least amount of time and most cost-effective way will require some engineering.

The Solution

Presenting this challenge to the Chase Power team was like giving kids the keys to a chocolate factory. A plan was formulated, along with several contingency plans. Failure would not be an option. The plan was presented to our client and immediately approved.

Before The Day

Before 72 batteries leave the Chase Power warehouse, they are each carefully tested to ensure they were in peak health. This is exactly the same process we have in place for all our single and three phase UPS batteries, no matter how big or small. Our warehouse is air conditioned at a consistent temperature and humidity allowing optimal battery health all year round. One of the reasons whyChase Power have very few warranty issues!

72 x 12V 110Ah M6 Rechargeable Sealed Lead Acid Front Terminal Batteries were selected for the job.

Battery features include:

- Absorbent Glass Mat (AGM) technology for superior performance

- Superb high-rate discharge characteristics ensures reliable performance in UPS and telecom applications

- Proven valve regulated technology that guarantees safe operation

- Rugged impact resistant ABS case and cover

- Thick plate design and efficient gas recombination yield a service life of 10 – 12 years in standby mode

- Front terminal design for ease of maintenance

The batteries and other gear is assembled and loaded ready for the journey to site.

On The Day

Cantilever truck allow room to move pallets

At sparrow’s chirp, we transport the batteries to site using a cantilever tailgated Medium Rigid (MR) truck, necessary to transport the 2.5 tonnes of batteries and other equipment required to complete the job. Prior to commencement of works, a JSA (Job Safety Analysis) is completed and signed off by the relevant engineers.

We have qualified forklift drivers on staff

A forklift is also transported to site to lift the pallets of batteries. We build a raised platform on the metal grate walkway to allow a pallet jack to roll the pallets into the switch room. (Way better than carrying them one by one up that metal rung ladder, we are sure you will agree!)

Unloading the Batteries

Prior to removing the batteries, the UPS is placed in bypass so there is no interruption to the load. Each string of batteries is isolated and locked off at the Battery Circuit Breaker. Old batteries are removed, placed onto pallets, forklifted down and loaded back onto the truck. New batteries are man-handled into place and torqued to the required Neuton Metres (Nm). Our scissor lift battery lifter makes relatively light work of this otherwise enormously heavy job.

The scissor lift is very very handy!

On completion, rubbish is removed and recycled, forklift and MR truck are returned and the batteries are recycled following relevant Australian standards in battery disposal.

Removing the old batteries

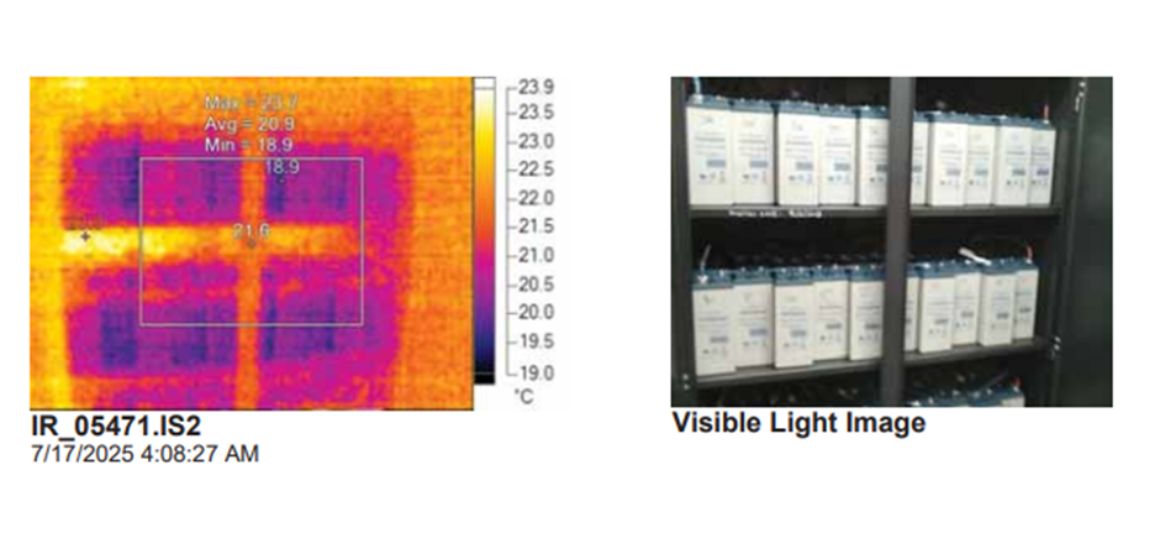

With the old batteries out of the way, a series of safety and post installation battery performance tests were undertaken which included thermal scans to check for hot spots and any possible faults.

Thermal Testing

The batteries were then connected and energised. The battery circuit breaker was closed and bought back online. A load test was conducted using the customers load prior to signing and approval by the site engineer.

Project Management

Project logistics was managed end to end by our Chase Power team on time and on budget. Right from the very first phone call to job completion, Chase Power delivered every step of the way. We provided flexibility where it was needed, expertise and trusted advice. Our staff are well qualified with several of our staff experienced forklift operators, medium and light rigid truck drivers, electrical engineers and technicians. Had the UPS required commissioning, we could have done that too.

After all the hard yakka was done, our technicians then collated and provided well documented service compliance reports.

But the job doesn’t end there. Chase Power provides 24/7 support. If for whatever reason there are issues with the UPS or batteries, Chase Power is always on call.

The Chase Power service division is a very dynamic part of our core offerings. We offer UPS preventative maintenance, UPS repair, UPS replacement… and of course battery replacements. How about optional extras? Absolutely. SNMP cards, rail kits, environmental monitoring, PDUs, bypass switches, cabinets and more.

Chase Power single and three phase UPSs can be found in airports, hospitals, mine sites, manufacturing plants, government buildings, ambulance stations, fire stations, banks, data centres and other critical infrastructure.

For trusted and experienced UPS advice, you know who to call.

Comments are closed.